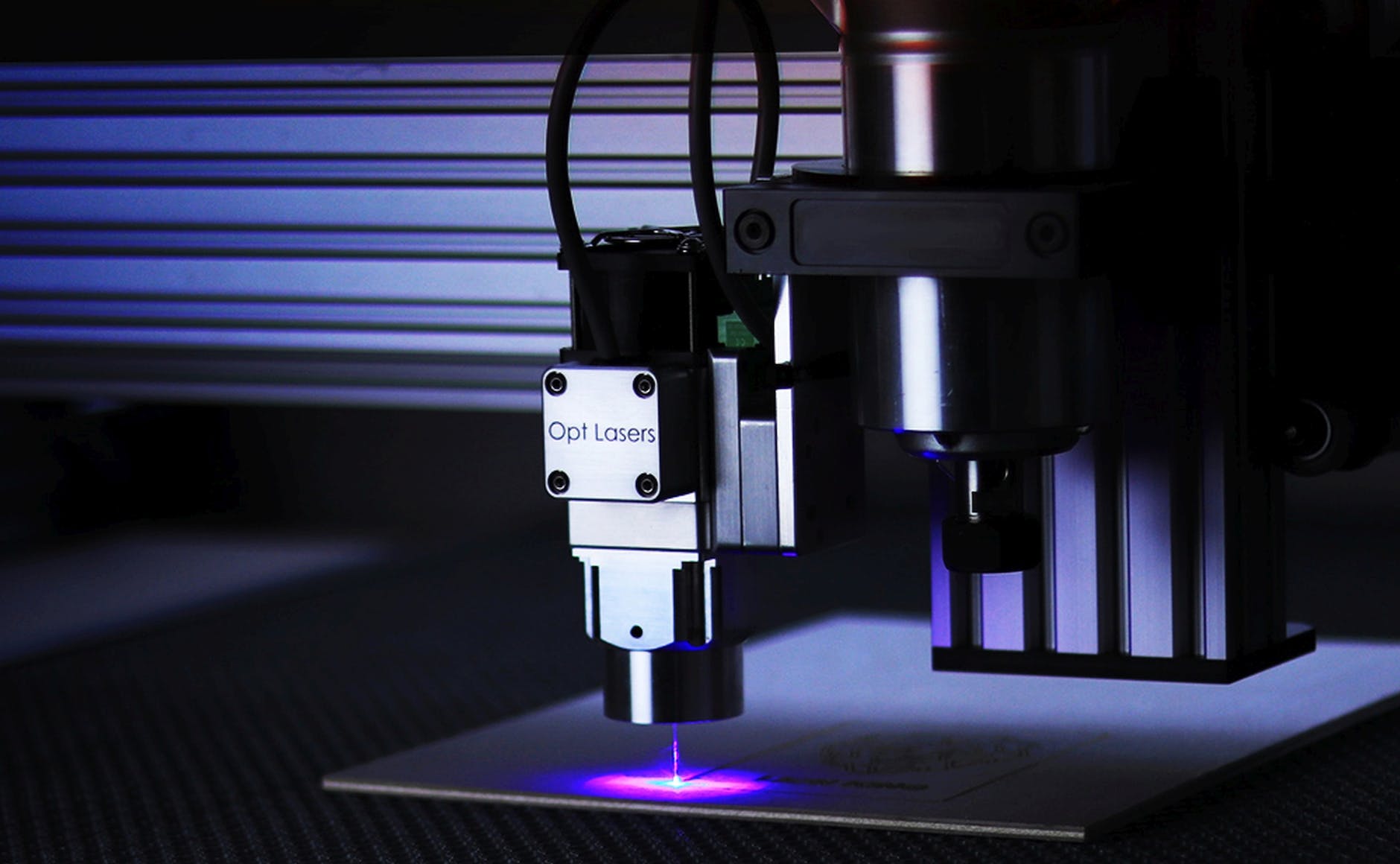

Laser cutting is a revolutionary material processing technique that uses a highly concentrated beam of light to precisely cut various types of materials. This technology has become indispensable in many industrial sectors, including mechanical engineering, automotive, construction and many others. Thanks to its ability to ensure exceptional precision and clean cut, laser cutting has become synonymous with efficiency and quality in modern manufacturing.

Why is laser cutting so popular?

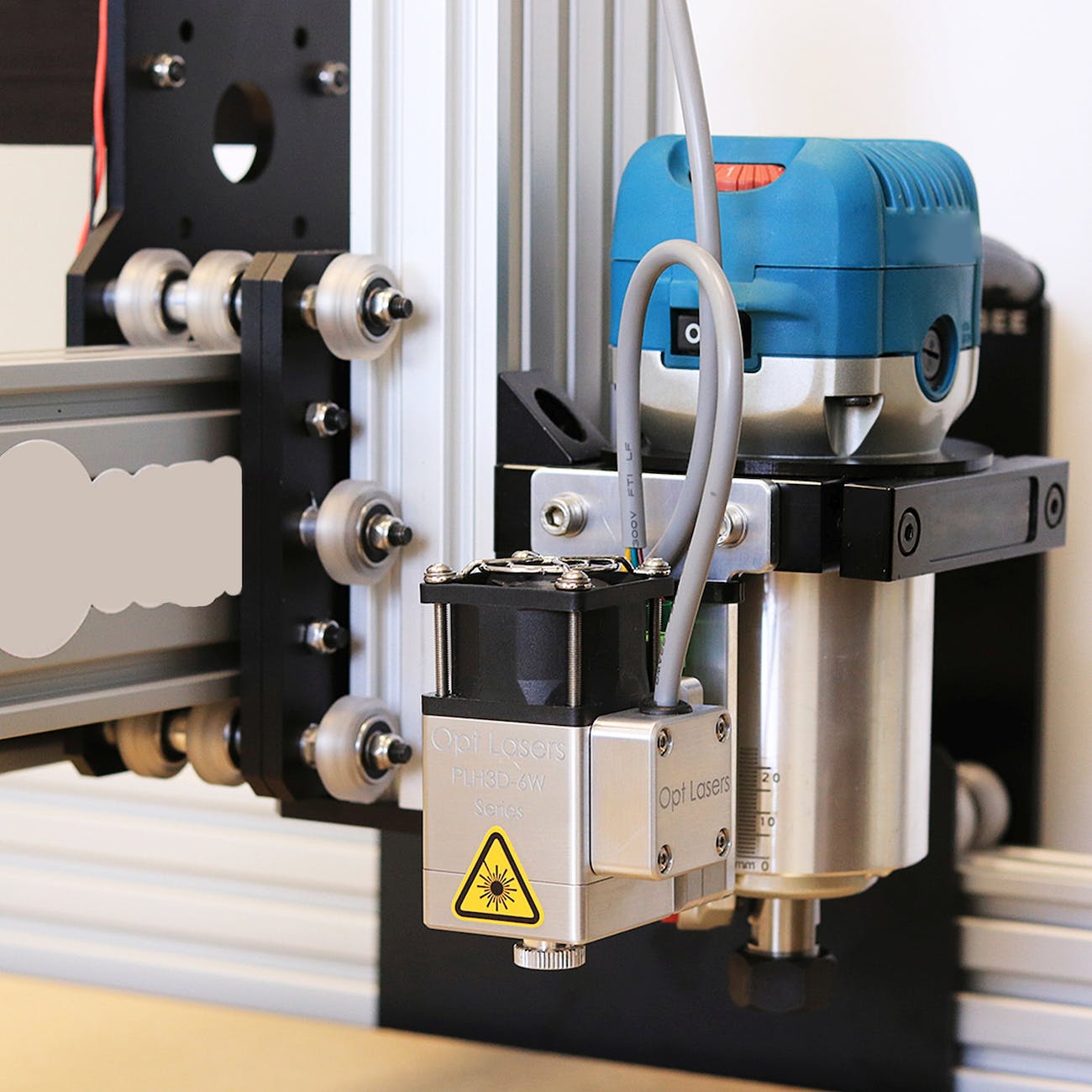

One of the key advantages of laser cutting lies in its ability to handle complex shapes and delicate materials without contact with the material itself. This eliminates the risk of mechanical damage or deformation, making the process ideal for precision machining. In addition, high efficiency and cutting speed enable the production of large series of products in a short period of time, which significantly reduces production costs.

How does laser cutting work?

The heart of any laser cutting system is a laser – a device that generates a focused beam of high energy light. When this beam is focused to a very small point, the material at the focus point is heated to extreme temperatures, resulting in melting, burning, or vaporization, depending on the type of material. The process is extremely fast and precise, allowing thin lines to be cut through the material with minimal clearance.

Application of laser cutting in industry

Laser cutting has found wide application in various industries thanks to its universality and adaptability. In the automotive industry, it is used to cut body parts and engine components with extreme precision. In construction, laser cutting of metal structures allows the creation of complex designs and shapes. Also, in electronics manufacturing, it is used to make precision components, such as printed circuit boards.

Advantages of laser cutting over traditional methods

Laser cutting offers numerous advantages over traditional cutting methods, including greater precision, speed and flexibility. The ability to easily adapt to cut different materials and shapes makes it extremely efficient for small and large batch production. In addition, smaller cutting clearance and minimization of material waste contribute to the sustainability of the process.

Challenges and limitations

Although laser cutting is extremely efficient, there are certain challenges and limitations. The cost of the initial investment in equipment can be high, which can be a barrier for small producers. Also, processing certain reflective materials, such as aluminum and copper, may require specialized lasers. However, the continuous development of technology and the appearance of more economical models of laser machines are gradually reducing these obstacles.

The future of laser cutting

Laser cutting technology continues to evolve, opening up new opportunities for manufacturing innovation. With the development of new types of lasers and the improvement of software support, a further increase in precision, speed and efficiency of cutting is expected. This will allow manufacturers to explore new designs and materials, further expanding the boundaries of what is possible in manufacturing.

We offer quality metal cutting services

Pimtool uses the latest laser machines to cut a variety of metals, including steel, aluminum, brass and copper. Find out more!

Frequently Asked Questions (FAQ)

Q: What materials can a laser cutter cut? A: Laser cutters can cut a wide variety of materials, including metal, plastic, wood, glass, and many others.

Q: How fast is las. cutting? A: Laser cutting speed depends on material type and thickness, but is generally much faster than traditional cutting methods.

Q: Is laser hair removal safe? A: Laser cutting is very safe when performed following proper safety procedures and using protective equipment.

Q: How is cutting equipment maintained ? A: Hairdressing equipment. cutting requires regular maintenance, including cleaning of the optical elements and checking of the cooling system, to ensure optimal operation and extend its life.

Conclusion

Laser cutting is a game-changing technology in industrial manufacturing, offering unparalleled precision, efficiency and flexibility. As technology advances, we can expect even more innovative applications that will further improve production processes. With continued investment in the development and application of laser cutting, the future looks bright for industries worldwide.

Previous articles

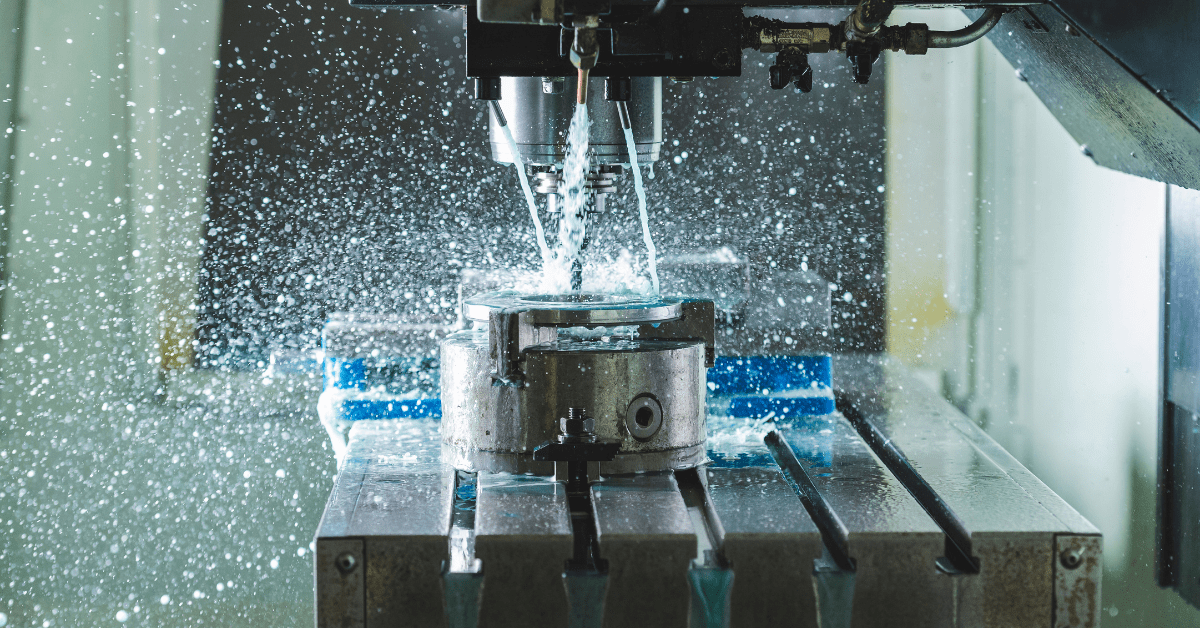

CNC metal processing: A combination of precision and engineering