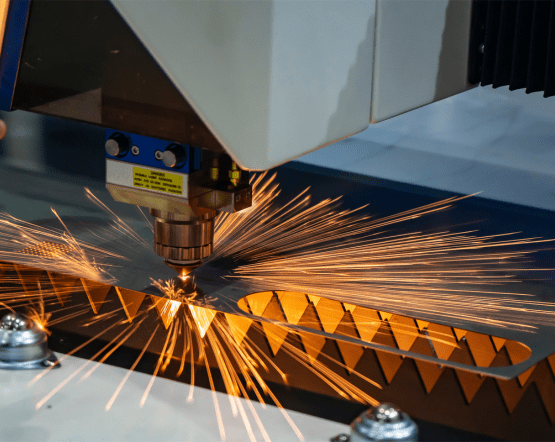

LASER CUTTING

Cnc Laser Metal Cutting

Laser cutting is a precise technology that enables metal cutting with high accuracy and minimal thermal impact on the material. Thanks to the most modern machine, the fiber laser, we are able to provide you with high quality cutting at very good prices.

We use the latest laser machines that allow cutting different types of metals, including steel , aluminum , brass and copper . This technology allows us to achieve complex and precise cuts with smooth edges.

Cnc Laser Metal Cutting: Advantages

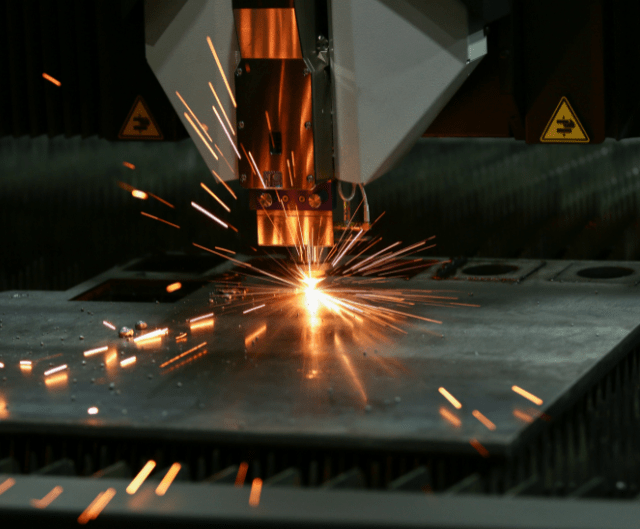

The advantages of our laser metal cutting service are numerous. CNC laser metal cutting brings exceptional accuracy and repeatability that is crucial in modern industry. This technology enables precise laser cutting of thin and thick materials, without deformation and additional processing. It is ideal for all types of serial and individual production, especially when a superior finish and minimal waste is required.

Types of metals we can cut

There are different types of metal that can be cut with a laser. This technique is used to precisely and efficiently cut metal, providing a clean and accurate cut. Some of the most commonly cut metals are described below, including steel, aluminum, stainless steel, brass, and copper.

- Steel sheets

- Stainless steel

- Copper

- Aluminum

When it comes to steel, laser cutting can be applied to high strength steels, low carbon steels, alloy steels and many other types of steel. Steel plates of different thicknesses can be cut with a laser.

Aluminum is another common metal that can be laser cut. Lasers are used for cutting aluminum sheets, profiles and pipes. The advantage of laser cutting aluminum is that high precision is achieved, and the thermal impact on the metal is minimal.

Stainless steel can also be laser cut. This metal is often used in the food industry, the medical industry and the automotive industry. Laser cutting allows precise cutting of stainless steel without damaging the surface or creating ribs.

Brass and copper are metals that are often used for decorative purposes. Brass and copper plates of different thicknesses can be cut with a laser. Laser cutting makes it possible to create complex and detailed shapes in these metals.

It is important to note that the selection of the appropriate laser and cutting parameters is adjusted to the type of metal and the thickness of the material being cut.

Our expert team with many years of experience guarantees top quality metal cutting and fast delivery. Whether you need metal cutting for industrial or creative purposes, we are here to provide you with a professional laser metal cutting service to meet your needs.

For all your laser cutting needs, feel free to contact us. Our expert team is ready to answer all your questions, provide additional information and help you realize your projects.

CNC laser metal cutting Kragujevac

If you are looking for CNC laser metal cutting in Kragujevac , we offer a professional and fast service for all the needs of locksmith, automotive and industrial production. Our equipment enables laser cutting Kragujevac with maximum accuracy, short delivery times and stable quality. It is ideal for companies that want a local and reliable partner.

FREQUENTLY ASKED QUESTIONS

Laser metal cutting can be applied to a variety of metals, including steel, aluminum, brass, copper, stainless steel, and many other alloys.

The laser enables high precision, thin cuts and smooth edges, with minimal thermal impact on the material. Also, laser cutting is fast, efficient and flexible, does not require additional tools and molds, which results in saving time and reducing costs.

-

The maximum thickness of metal that the laser can cut depends on the power of the laser and the type of metal. Our equipment can cut metals up to a certain thickness limit, so it is best to contact us with specific requirements.

Yes, laser metal cutting allows the creation of complex shapes and designs. The laser is easily programmed to cut different shapes and can precisely follow the desired path.

The processing time depends on the complexity of the design, the thickness of the metal and the total volume of the order. Our team will give you an accurate estimate of the processing time when you provide us with the details of your order.

Looking for the best solution for your needs?

Contact us and send a drawing or inquiry — we respond quickly and provide a clear, precise quote.

If you want detailed marking or decorative elements, take a look at the laser engraving service, ideal for fine and precise processing of various materials.