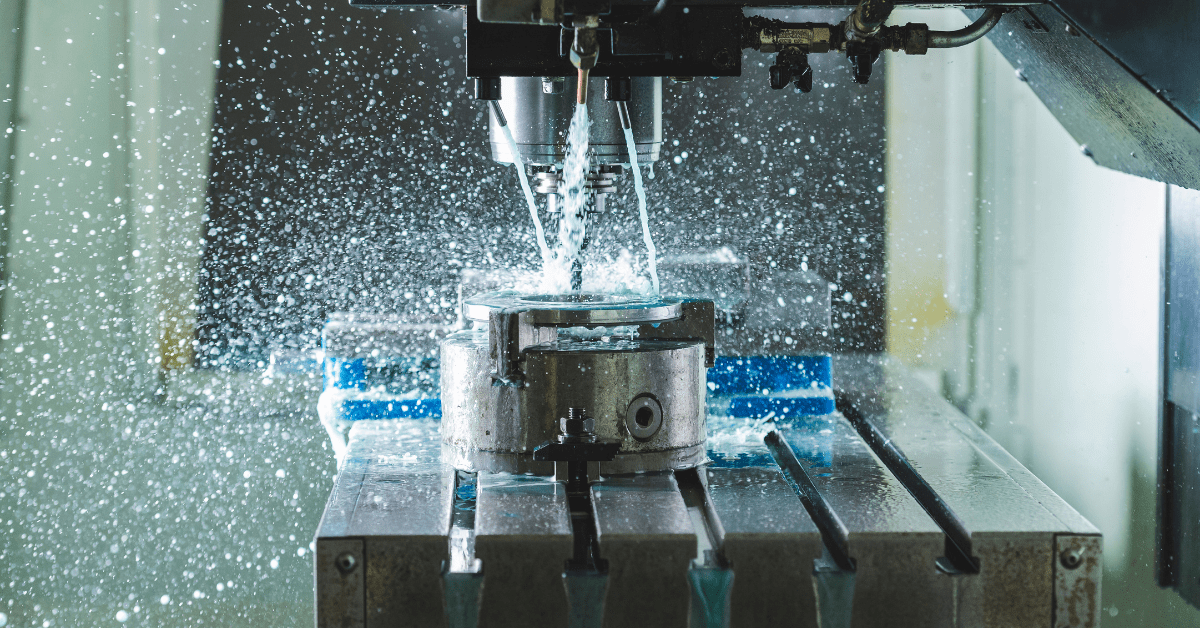

CNC metalworking has revolutionized the manufacturing industry, enabling precision, efficiency and innovation in product design and functionality. Have you ever wondered how the complex metal components of your favorite devices get their shape? Behind the scenes, CNC metalworking plays a key role, transforming raw blocks of metal into the precision parts that power the modern world.

Revealing the Secrets of CNC Metalworking

CNC (Computer Numerical Control) metalworking uses computer systems to control machine tools that shape and modify metal. This technology allows manufacturers to create complex and detailed parts with extreme precision.

How are CNC machines changing the game?

Imagine the process of making a precision metal part used in airplanes or automobiles. CNC machines allow this process to be carried out faster, more accurately and with fewer errors compared to traditional machining methods.

Precision that pushes boundaries

One of the key aspects of CNC metalworking is its ability to produce parts that consistently meet specifications, regardless of the complexity of the design. This opens the door to innovation in various industries, from automotive to aeronautics.

Application of CNC Metalworking in Real Life

The story of CNC metalworking is not just a technological one; it is a story about the transformation of ideas into reality. From art installations to vital spacecraft components, CNC metal crafting plays an unimaginable role.

Automotive Industry: A Revolution in Manufacturing

In the automotive industry, CNC metalworking is used to manufacture engine components, transmissions and suspension systems. The precision and reliability that CNC machines provide are essential to vehicle safety and performance.

Aviation and space exploration: Flight to precision

In aviation, CNC metalworking enables the production of highly precise components that can withstand extreme conditions. In space missions, every part must be perfect, and CNC technology is key in achieving that goal.

The future of CNC Metalworking: Where are we going?

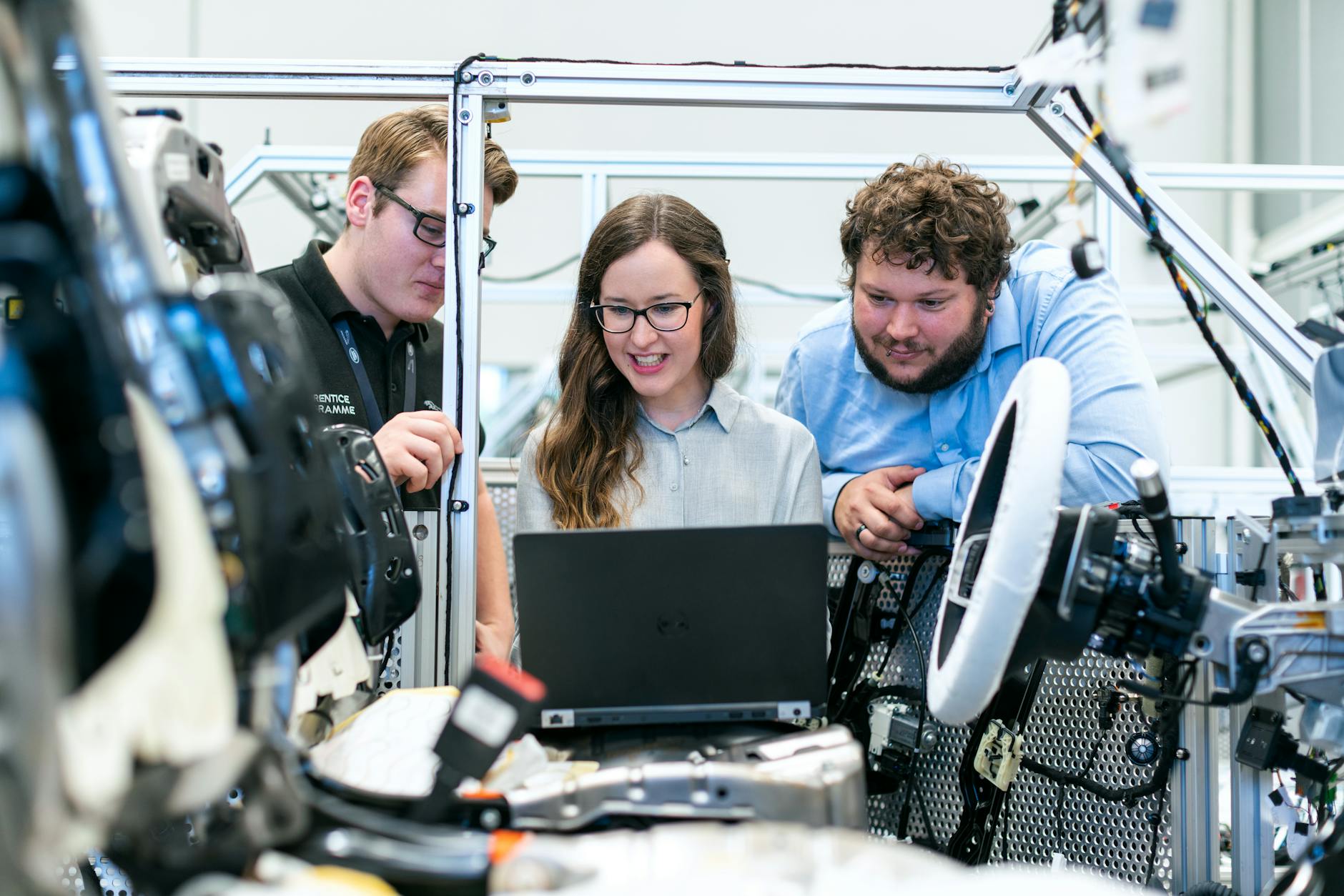

Innovations in CNC technology continue to push the boundaries of what is possible, with new materials and techniques promising to make the industry even more efficient and sustainable. Digitization and automation are playing a key role in shaping the future of CNC metalworking, promising even greater precision and lower production costs.

Sustainability and innovation

Sustainability is becoming an increasingly important factor in manufacturing, and CNC metalworking is no exception. The technology allows manufacturers to reduce waste and increase efficiency, thus contributing to the preservation of the environment.

Conclusion

CNC metalworking is not just about machines and tools; it’s about the journey from idea to realization, where precision and innovation go hand in hand. As technology continues to advance, we can only expect even greater wonders in the world of metalworking.

Previous articles

Frequently Asked Questions (FAQ)

Q: What does CNC mean? A: CNC stands for Computer Numerical Control, which means machine control by computer for precise processing of materials.

Q: How do CNC machines contribute to precision in manufacturing? A: CNC machines use detailed computer programs to control the tools, allowing parts to be manufactured with extremely high precision and consistency.

Q: In which industries is CNC metalworking most commonly used? A: CNC metalworking is widely used in the automotive, aerospace, defense, medical, and aerospace industries, among others.

Q: How does CNC technology contribute to sustainability? A: CNC technology reduces the amount of waste during production through precise material processing and process optimization, thereby contributing to environmental sustainability.